In order to locate any surface-breaking defects in an aluminum casting, a Dye Penetrant Inspection (DPI), also called Liquid Penetrant Testing (LPT) can be performed. During this non-destructive testing process, a liquid penetrant testing technician will look for surface porosity defects, leaks and cracks that could end up being very costly if left undetected. There are 6 steps to a dye penetrant inspection:

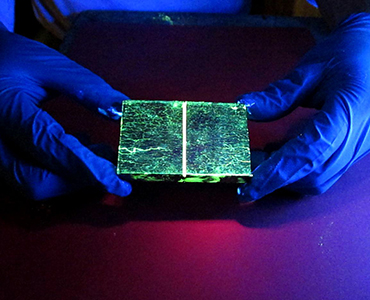

In order to locate any surface-breaking defects in an aluminum casting, a Dye Penetrant Inspection (DPI), also called Liquid Penetrant Testing (LPT) can be performed. During this non-destructive testing process, a liquid penetrant testing technician will look for surface porosity defects, leaks and cracks that could end up being very costly if left undetected. There are 6 steps to a dye penetrant inspection:

- Pre-cleaning

- Application of Penetrant

- Excess Penetrant Removal

- Application of Developer

- Inspection

- Post Cleaning

DPI is performed by AeroCom Inspection, who we have been partnered with for over 30 years.

Contact us for more details on our aluminum casting services. Alumco is an ISO 9001:2015 certified company with over 50 years of foundry experience servicing clients from Southern Ontario and North America.