To improve mechanical and physical properties, sand and permanent mould castings may be heat treated.

To improve mechanical and physical properties, sand and permanent mould castings may be heat treated.

From selecting the alloy and casting process to the proper thermal treatment to be used, you can count on us. Alumco provides experience and an extensive knowledge of the heat treating processes and the effects they have on the metallurgical structure of aluminum castings.

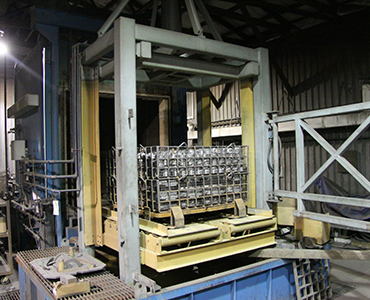

For production, we use state of the art heat treatment equipment to achieve optimal results.

Contact us for more details or to schedule an appointment. Our facilities are located just a few miles south of Hamilton Ontario.