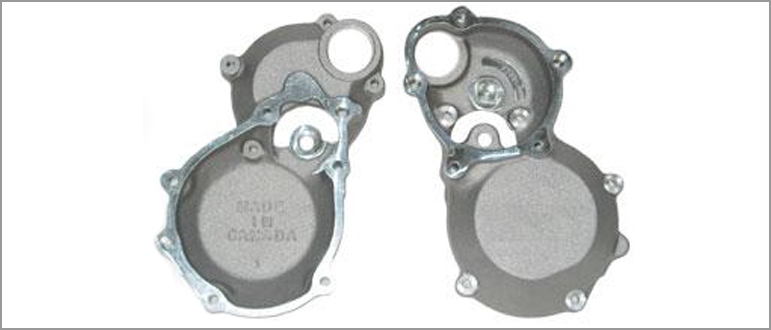

MOTORCYCLE PARTS

PROJECT: Motorcycle parts

A potential customer asked us to produce a series of motorcycle casings. As we investigated the product and process design, we identified an opportunity to significantly reduce subsequent trim machining operations (of the casing) if we could utilize kiss gating on the top of the motorcycle part where our customer currently machines. While kiss gating is a known technique to reduce the amount of material to be machined, it has negative implications in that it changes and reduces material flow into the mold cavity.

Additionally, the motorcycle casing application has areas of thin cross sectional area as well as thick flanges, where the difference in cross sectional area results in significant processing problems relating to shrink and porosity (caused by the thin areas freezing off before the thick areas).

Also, some applications required that the casing be cast concave side up, which requires tooling with suspended sand to form the concave shape. We knew that the material flow associated with kiss gating would cause the sand to fall away from the mold resulting in out of print parts, poor surface finish, and impurities in the part. Through experimentation we had gained significant knowledge pertaining to processing of motorcycle engine casings in regular and inverted positions. As a result of the development of the kiss gating and riser systems, and pour temperature experimentation, we have developed a product and process that reduces the need for further processing by to remove the gates and risers by 75%. Our customer was so pleased with our tooling and process design that we have been sourced on a total of eight additional motorcycle engine covers.